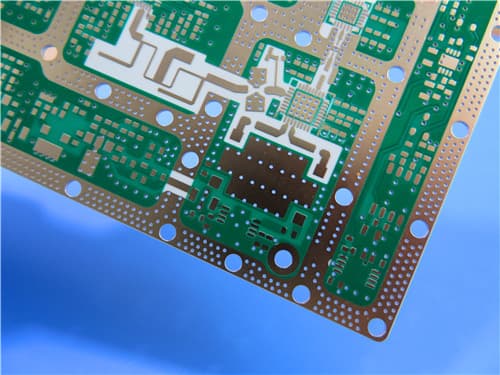

RO4350B LoPro 2-Layer 60.7mil ENEPIG PCB for High-Frequency Applications

1.RO4350B Low Profile Introduction

RO4350B low profile laminates use a proprietary Rogers' technology that allows reverse treated foil to bond to standard RO4350B dielectric. This results in a laminate with low conductor loss for improved insertion loss and signal integrity while maintaining the other desirable attributes of the standard RO4350B laminate system. RO4350B hydrocarbon ceramic laminates are designed to offer superior high frequency performance and low cost circuit fabrication. The result is a low loss material which can be fabricated using standard epoxy/glass (FR-4) processes and do not require specialized via preparation such as sodium etch for lower manufacturing cost.

2.Key Features

Stable Dielectric Constant: 3.48 ±0.05 at 10 GHz/23°C

Low Loss Characteristics: Dissipation factor of 0.0037 at 10 GHz/23°C

High Temperature Performance: Td > 390°C, High Tg greater than 280°C TMA

Effective Thermal Management: High Thermal Conductivity of 0.69 W/mK

Excellent Reliability: Low Z-axis coefficient of thermal expansion at 32 ppm/°C

Dimensional Stability: Copper matched CTE X-axis 10 ppm/°C, Y-axis 12 ppm/°C, Z-axis 32 ppm/°C (-55 to 288°C)

Safety Certified: UL 94-V0 Flammability

Modern Manufacturing: Lead free Process Compatible

3.Benefits

Enhanced High-Frequency Performance: Lower insertion loss allows for higher operating frequency designs (even greater than 40 GHz)

Improved Signal Quality: Reduced passive inter-modulation (PIM) for base station antennas

Superior Thermal Management: Improved thermal performance due to lower conductor loss

Design Flexibility: Multilayer PCB capability and design flexibility

Manufacturing Versatility: High temperature processing capability

Environmental Compliance: Meets environmental concerns and CAF resistant

4.PCB Construction Details

| Parameter | Specification |

|---|---|

| Base Material | RO4350B Low Profile |

| Layer Count | 2-Layer |

| Board Dimensions | 43mm × 56mm = 1PC |

| Minimum Trace/Space | 4/6 mils |

| Minimum Hole Size | 0.3mm |

| Blind Vias | No |

| Finished Board Thickness | 1.6mm |

| Finished Cu Weight | 1oz (1.4 mils) outer layers |

| Via Plating Thickness | 20 μm |

| Surface Finish | ENEPIG |

| Top Silkscreen | White |

| Bottom Silkscreen | No |

| Top Solder Mask | Green |

| Bottom Solder Mask | No |

| Electrical Test | 100% tested prior to shipment |

5.PCB Stackup (12-Layer Rigid Structure)

Copper Layer 1 - 35 μm

Rogers RO4350B LoPro Substrate - 60.7mil (1.542mm)

Copper Layer 2 - 35 μm

6.PCB Statistics:

Components: 11

Total Pads: 51

Thru Hole Pads: 23

Top SMT Pads: 28

Bottom SMT Pads: 0

Vias: 34

Nets: 2

7.Typical Applications

Digital applications such as servers, routers, and high speed back planes

Cellular base station antennas and power amplifiers

LNB's for direct broadcast satellites

RF Identification Tags

8.Quality Assurance

Artwork Format: Gerber RS-274-X

Quality Standard: IPC-Class-2

Availability: Worldwide